Laser Micromachining Setup Upgrade at Lawrence Berkeley Laboratory

With the help of Direct Machining Control, a micromachining setup at Lawrence Berkeley Laboratory was upgraded to expand the capabilities of controlling multiple devices. The setup is intended for the research and development using laser machining techniques for semiconductor machining. The setup was comprised of 4 axes Aerotech positioning system, galvo scanners, controlled with RTC4 card, a laser source emitting one of 3 wavelengths, cameras for machine vision, height sensor, power meter and other devices. DMC was installed to increase the efficiency of the R&D process by making the control of all the devices intuitive, visual and simple.

The customer had an R&D laser machining setup with multiple motion and tuning devices. The setup was upgraded with an additional laser source and new control software for easier use.

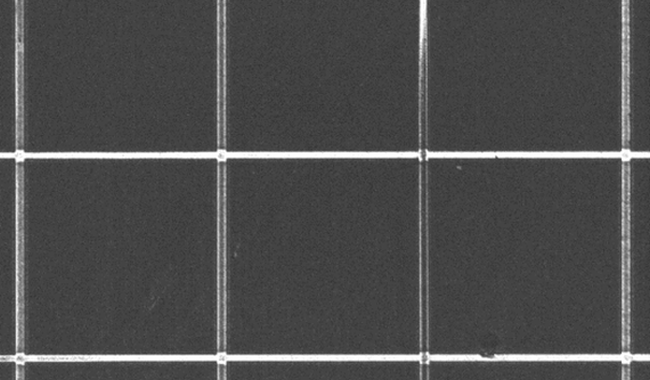

- Coordination of 4-axis positioning stages and galvo scanners. There was a need to trigger laser emissions from both Aerotech positioning stages using PSO function and RTC4 card.

- Automatic selection of laser wavelength. The laser source in the setup had a selection of 3 wavelengths, each with dedicated optical paths. Switching between them had to be quick and easy, with the ability to follow the same manufacturing workflows.

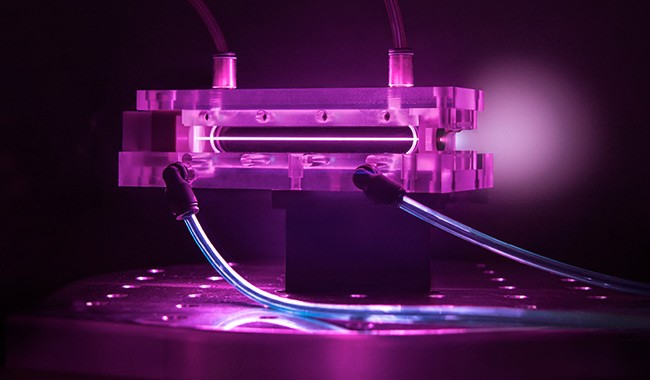

- Integration of a new laser system. An additional laser system with two wavelengths was installed. For both laser systems, parameters like power, frequency, wavelength as well as triggering had to be controlled within a single software interface.

- Alignment of the wafer. Since high precision was paramount to users application a visual alignment procedure had to be used.

- Precise laser power control. The exact laser power load on the sample (after the laser beam traverses the optical path) had to be known and controlled.

- Wafer thickness measurement and automatic recipe adjustment to it.

- Control of additional devices i.e. RGB lighting, vacuum chuck, dust evacuation, vacuum for devices, etc.

After discussions with the customer, the following solutions were implemented using DMC PRO laser machining software.

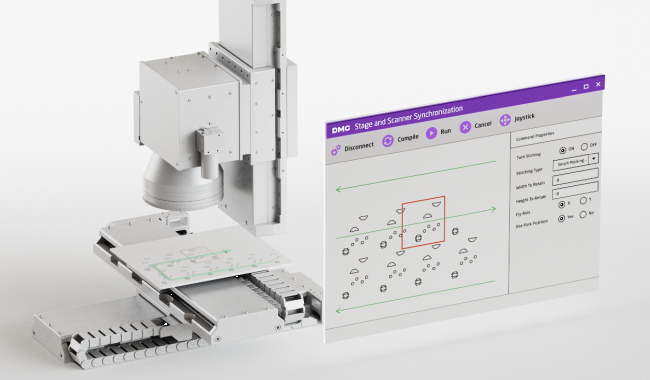

- DMC controls both positioning stages and galvo scanners. Objects that are machined with scanners are moved to the galvo field of view automatically. Large objects can be split and Stitching Tool can be used to coordinate motion between scanners and stages. Triggering and machining device is selected via the software interface.

- The controls of specific laser sources were implemented using the API provided by the manufacturers. The laser wavelength can be selected directly via the DMC interface. The beam path is selected via digital I/O. User added toggles in the Ribbon Menu to select the optical path.

- Support for the new laser system was developed using the API provided. Both laser sources are controlled via the DMC interface including power, laser frequency and wavelength parameters.

- Two cameras for wafer alignment were mounted. Both of them are calibrated via the DMC interface and are either used for visual inspection or manual and automatic alignment. Also, samples can be moved between laser and cameras with a single mouse click for quick and convenient inspection.

- An external power meter was installed to measure power load on the surface. Readings from the power meter are acquired and displayed in the DMC interface. Automatic power adjustment to a set value is implemented using a closed control loop with feedback from a power meter.

- Wafer thickness is measured using the installed pneumatic sensor. Its measurements can be used automatically in the recipe to adjust parameters to different wafer thicknesses.

- A special tool for RGB lighting control was developed. Additional devices are controlled via digital outputs and toggle buttons are created in the Ribbon Menu.